Multi Purpose Mixed Fire Vehicle

MULTIPURPOSE MIXED FIRE VEHICLE MANUFACTURER: KARBA ORIGIN: TURKEY

MODEL: 50001500/DCP5003000NH

TECHNICAL SPECIFICATION

| No | Content | Technical Specification | ||

| A | Genral information | Model: 50001500/DCP5003000NH | ||

| Type | Multi purpose mixed fire vehicle | |||

| Driven wheel | 4x2 | |||

| Cabin | Single Cabin | |||

| Water tank/foam Tank/DCP Capacity | 5.000 water tank/500liter foam tank /500 Kg DCP | |||

| Qualification | New 100% | |||

| B | Technical Specification | |||

| I | Chassis | Model: IVECO ML180E28 Euro - 5 Manufacturer: IVECO | ||

| 1 | General infomation | |||

| Type | Specialized vehicle | |||

| Drive wheel | 4x2 | |||

| Seats | Single Cabin , 02 seats including driver | |||

| Engine | 280E5 - Diesel | |||

| Engine Power | 275HP | |||

| Gearbox type | Manual 9 Speed – ZF9S1110TO | |||

| Capacity | 18.000kg | |||

| Brake system | Disc Brakes with ABS | |||

| Whellbase | 3690mm |

|||

| Front tires | 295/80R22,5 |

|||

| Rear tires | 295/80R22,5 |

|||

| Tires | 02 front tires + 04 rear tires (in total 06 tires) | |||

| Compressor | 360CC | |||

| Fuel tank capacity | 200 liter | |||

| Front axle load | 7.100kg | |||

| Rear axle load | 11.500kg | |||

| Product standard | ISO45001:2018; TS EN 1501-1+A1; TS EN1028-1+A1; ISO10002:2018; EN1846-1:2011; EN1846-2:2009+A1:2013; EN1846-3:2013; TSEK VİDANJÖR; TSEK DAMPERLİ KASA | |||

| Design | Will be designed in such a way to allow maximum accessibility to all areas. Covered by anti-slip material with light alloy handrails. | |||

| Roof Access |

One unit climbing ladder will be fixed at the rear part of the vehicle to access the roof of the vehicle. Handgrips will be provided on the ladder. |

|||

| Body | There are 5 storage lockers surrounding the vehicle. Lockers are closed by lockable aluminum roller shutters. All locks on the vehicle can be opened by one universal key. The base of the lockers will be covered with aluminum plates. Drain holes are provided on the floor of the compartment to supply the water drainage. The superstructure is covered with steel and steel frame, all superstructure components are assembled on a subframe. | |||

| Water tank | ||||

| Type | Modular type tank placed between the two locker compartments. | |||

| Capacity / Material | 5.000 liters/ AISI 304 Stainless Steel | |||

| Baffle Plates | There are horizontal and vertical walls inside of AISI304 material | |||

| Manhole | 500mm with lid and with mechanical lock | |||

| Filling the Tank | 2 doors 2 sides- 2.5 " with GOST standard coupling | |||

| Tank Drainage | 2 inch bottom outlet with ball valve. | |||

| Sewer pipes | Tube to remove excess air and water in the tank |

|||

| Level Indicator | Located on the dashboard. |

|||

| Foam tank |

|

|||

| Capacity / Material | 500 liters / AISI 316 Stainless Steel | |||

| Filling | 4 inch filling valve on top of the tank also for cleaning purpose | |||

| Cleaning | 2 inch spherical valve for draining. | |||

| DCP (powder) unit | ||||

| Capacity | 500 kg | |||

| Material | 6 mm St-37, Cylindrical, equipped with control panel | |||

| Location | In the front locker | |||

| Nitrogen Tubes | 2 unit x 20 liter regulator | |||

| Operation Pressure | 14kg/cm² | |||

| Reel | 1 unit 1” x 30 m hose reel with powder gun |

|||

| Operation | Manual |

|||

| DCP unit Standard | EN ISO12100:2010, EN ISO 13857: 2008, EN 349: 1993+ A1:2008 | |||

| Fire pump |  |

|||

| Manufacturer | KARBA | |||

| Model | KARBA 3000NH | |||

| Fire pupm | European technology - synchronous by fire truck manufacturer, 5 stage centrifugal multi-pressure, 2 normal pressure, 3 high pressure | |||

| Driven Type | PTO | |||

| Material | Body & Fan will be manufactured from light alloy aluminum and the pump shaft will be manufactured from Stainless Steel. Karba pump can operate with salty sea water | |||

| Pump production technology | Karba | |||

| Production standart | TS EN 1028-1:A1:2011 TS EN 1028-2+A1:2009 | |||

| Capacity |

3000 lpm at 10 bar 250 lpm at 40 bar |

|||

| Outlets | 2x 2 inch pump inlets with globe valve with GOST coupling 2x 2.5 inch pump inlets with GOST coupling | |||

Suction |

1 unit 4 inch suction nozzle with GOST coupling. KARBA pump has a capability to suck water from 7 m geographical depth. | |||

| Foam Proportion | 1% - 6% automatic foam proportioning, the proportion ratio can be adjusted by a manual lever | |||

| Control Panel | Located in the rear pump compartment. | |||

| Water/foam monitor |  |

|||

| Manufacturer | KARBA | |||

| Capacity | 2.400 LPM at 8-10 bars, control by hand | |||

| Production technology | Integrated European technology manufactured by fire truck assembly manufacturers | |||

| Placement | On front of the vehicle roof- front | |||

| Control | Manually from roof of the vehicle | |||

| Standard | EN ISO12100:2010, EN ISO13857:2008, EN349:1993+A1:2008 | |||

| Throwing Distance | 60 meters water and 50 meters foam | |||

| Movement | 360o horizontally and from -15o to 75o vertical, karba jetting nozzle | |||

| Nozzle | Karba Jetting / Spraying Nozzle | |||

| Hose reel |  |

|||

| Manufacturer | Karba | |||

| Location | At rear left or rear right side of the vehicle | |||

| Type | Made of aluminum molding, resistant to high pressure. | |||

| Hose | 1 inch x 50m, unbreakable and uncrushable | |||

| Nozzle | Jetting/Spraying Nozzle with hand grip | |||

| Opening | Manual | |||

| Rewinding | Electrical/manual | |||

| Accessories | ||||

| 3 section 9 m aluminum portable ladder | 01 unit | |||

| 4” 3m Suction Hose with GOST couplings. | 02 unit | |||

| 2” 20m quality Fire Hoses with GOST couplings. | 04 units | |||

| 2 ½” 20m quality Fire Hoses with GOST couplings. | 04 units | |||

| 4” Suction Strainer | 01 unit | |||

| Straight flow shut off valve branch-pipe nozzle | 02 units | |||

| ABC coupling spanner | 01 unit | |||

| Front Bumper Winch | 01 unit | |||

| Electrical installation | ||||

| American Light bar | ||||

| 4 different siren system and PAS (Public Address System) | ||||

| Lockers will be illuminated | ||||

|

On two sides, front and rear of the vehicle there will be flashing warning lights |

||||

|

Outside projector light mounted on the rear-top of the vehicle |

||||

| 1 unit Telescopic Projector on the roof | ||||

| 1 | Radio Isotope Identification Device SPIR-ACE | |||

| Model | SPIR-ACE | |||

| Manufacture | Mirion technologies (Canberra), inc | |||

| Origin | USA | |||

|

||||

| Features | ||||

| Applications: radiation security, nuclear accident, radioactive source measurement. | ||||

| Auto stabilization, amplification, no standard radioactive source required | ||||

|

Externally connected alpha and beta contamination probes are available |

||||

| Internalmapping capabilities | ||||

| Direct data transmission and accessibility | ||||

| Specification | ||||

| Detectors | - NaI(Tl) version: dia 35 mm x 51 mm (1.4 in. dia x 2 in.) - Energy compensated GM tube for high gamma dose rate - Optional external alpha/beta GMP-25™ contamination probe | |||

| Energy range | 25 keV to 3 MeV (gamma) | |||

| Gamma dose rate range | 0.001 μSv/h to 100 mSv/h (0.1 μR/hr to 10 R/hr) | |||

| Identification | - Fast digital MCA, 1024 channels, throughput >100 000 cps - Seven libraries containing 80 nuclides - Identifies up to eight nuclides simultaneously - Detection and identification performance exceeds ANSI N42-34, IEC62327 and IAEA NSS 1 | |||

| Touch screen | 4.3 in. color LCD, Fast display update (every 0.25 s) | |||

| Alarm indicators | LEDs, vibrator and sound (81db@30cm) | |||

| Connectivity | - Internet connection by Wi-Fi or phone, - Record location of measurements/events, - Micro USB connection, Wireless connection (GPS; cellular; Wifi) | |||

| Measurement mode | Measurement mode with alarm: automatically collect and recognize when alarm, manual measurement mode (start/stop/resume) | |||

| Memory |

4GB SD card, event/spectrum memory capacity: >50000 |

|||

| Water and dust | IP65 | |||

| Operating temperature range NaI | -20 °C to +55 °C, 93% relative humidity at 40 °C | |||

| Electrical | Li-ion rechargeable, built-in charger, replaceable, 6700mAh, 3.6V, Battery life: 8.5 hours. Charge time: 5 hours with USB adapter. | |||

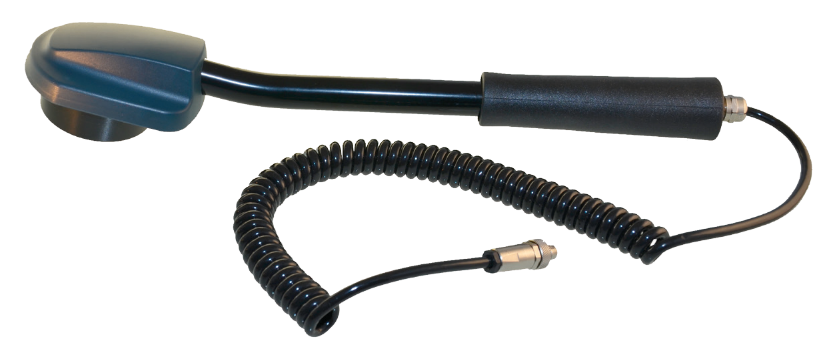

| * Alpha/beta external contamination probe |  |

|||

| Model | GMP-25 | |||

| Manufacture | Mirion technologies (Canberra), inc | |||

| Origin | USA | |||

| Probe is intended for monitoring alpha, beta, gamma and X-ray radiation. | ||||

| Energy range | Gamma > 6 keV, beta > 100 keV and alpha > 2 MeV | |||

| Detector type | GM tube 7313 | |||

| Pulse rate range | 0 - 50 000 cps | |||

| Mica window with active area | 15.5 cm2 (6.1 in2); window thickness: 1.5 - 2 mg/cm2 | |||

| Sensitivity |

2.8 cps (170cpm) for 90Sr/90Y uniform source of 0.37 Bq/cm2 |

|||

| Efficiency (cps / Bq) | - Am-241, α,E: 5,4 MeV: > 15% - C-14 β, Emean: 50 KeV: > 7 ± 1% - Sr-90/Y-90, β, Emean: 0,8 MeV: > 35 ± 4% - Cl-36, β, Emean: 0,27 MeV: > 29 ± 4% | |||

| MDA | - Am-241, α,E: 5,4 MeV: ≤ 0,26 Bq/cm² - C-14 β, Emean: 50 KeV: ≤ 0,55 Bq/cm² - Sr-90/Y-90, β, Emean: 0,8 MeV: ≤ 0,11 Bq/cm² - Cl-36, β, Emean: 0,27 MeV: ≤ 0,13 Bq/cm² | |||

| Equipment provided includes | - 01 external alpha and beta contamination probe and 1.5m extension cable - Transportation and storage case - USB AC power adapter - Micro USB cable/Hand strap/Earphones - Calibration certificate of equipment - 01 KCL uses fast power standard for equipment | |||

| 2 | Chainsaw |  |

||

| Model | 365 | |||

| Manufacture | Husqvarna | |||

| Origin | Sweden | |||

| Structure | 01 chainsaw, 01 chain, 01 tracks | |||

| Engine type | Air-cooled 2-stroke gasoline engine | |||

| Power output | 3.4kW | |||

| Engine technology | X-TORQ | |||

| Cylinder displacement | 65.1 cm3 | |||

| Idling speed | 2700 rpm | |||

| Maximum power speed | 9000 rpm | |||

| Cylinder diameter | 48mm | |||

| Cylinder journey | 36mm | |||

| Ignition system | SEM AM50 | |||

| Electrode gap | 0.5mm | |||

| Spark plug | NGK BPMR7A | |||

| Carburettor | C3M-EL2B | |||

| Starter | Smartstart technology brings quick and easy operation | |||

| Fuel tank volume | 0.77 L | |||

| Oil tank volume | 0.44 L | |||

| Oil pump type | Automatic | |||

| Oil pump capacity | 4-20ml/min | |||

| Chanin pitch | 3/8 inch | |||

| Recommended bar length | 38-70cm | |||

| Chain speed at max power | 20.7m/s | |||

| Equivalent vibration level (ahv,eq) front/rear handle | 3,6/3,5m/s2 | |||

| Sound pressure level at operators ear | 102.5 dB(A) | |||

| Weight (excl. cutting equipment) | 6kg | |||